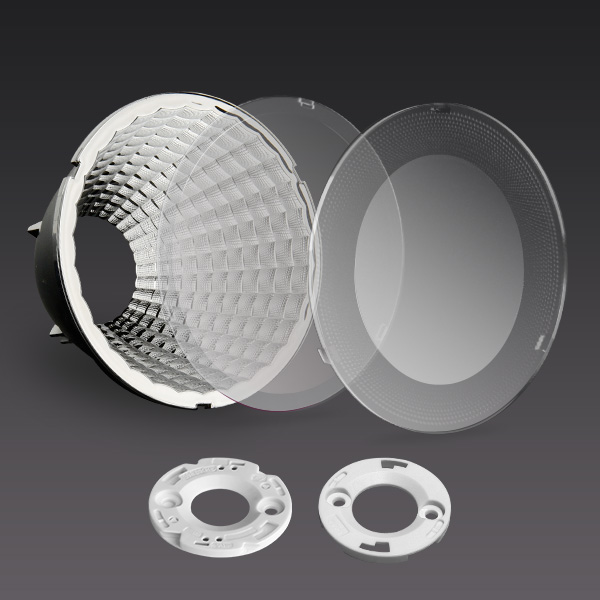

Plastic Reflector

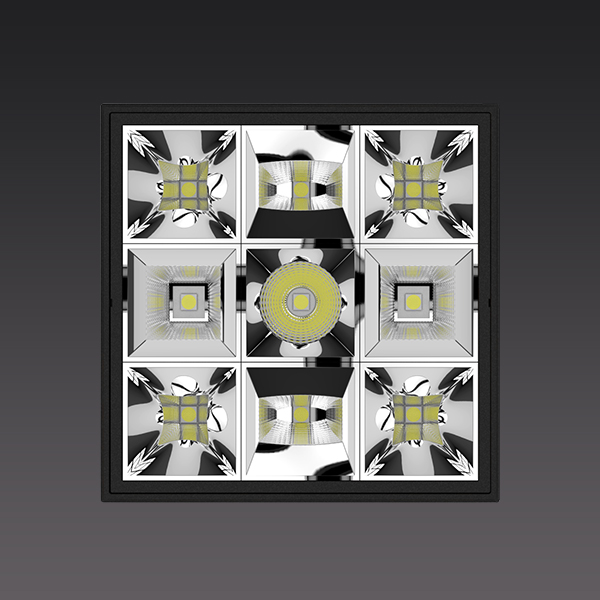

PC Reflector is an optical component made of polycarbonate material, produced through precision injection molding and vacuum metalized the optical surface. Its reflectivity can be 88% or above. The PC injection techonlogy is particularly suitable for manufacturing optics with complex and unique structures such as square, irregular shape and linear types. The product has strong impact resistance and simple production steps. Multi-cavity mold, single-step forming. PC reflectors are extensively applied in track lights, recessed lights, and spotlights for both commercial and industrial lighting applications.

PC Reflector Products

Nata produce wide range of PC reflectors. The size range from the diameter 25mm, 30mm, 35mm, 45mm, 50mm, 63mm, 69mm, 70mm, 75mm, to square shape and linear types. These reflectors offer various beam angles and finishing such as specular, diffuse, matt and fashion colors such as dark light, cooper, gold, bronze, champagne, gun ect. The products are equipped with various mounting alternatives, including soldering or ZHAGA standard holders.

Global PC Reflector Manufacturer and Supplier

Nata provide professional optical design services , prototype, molding and production for global lighting brands. The product are widely used in track lights, spotlights, downlights, wall washer lights, linear lights, flood lights, street lights, high bay lights, stage lights, photography lights, car lights, automobile lighting and other special lightings applications.

PC Reflector OEM/ODM

95% of customers are satisfied with our OEM/ODM services! Nata is equipped with professional R&D team. We offer ODM service and one-stop shop to each client. We are familiar with custom design project. We have systematic procedures to communicate with our customers. Once we got the requirement and proceed the evaluation, our designer team would prepare detailed simulation analysis reports and recommendations to customer and make sure no misunderstanding of each other. For urgent projects, we are willing to speed up the process minimum 10 days from design, tooling to sampling. Please feel free to contact us.