Quality First

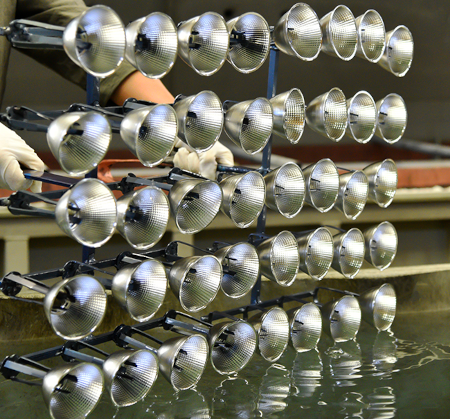

Precision optical mold manufacturing plant to ensure high quality of optical products.

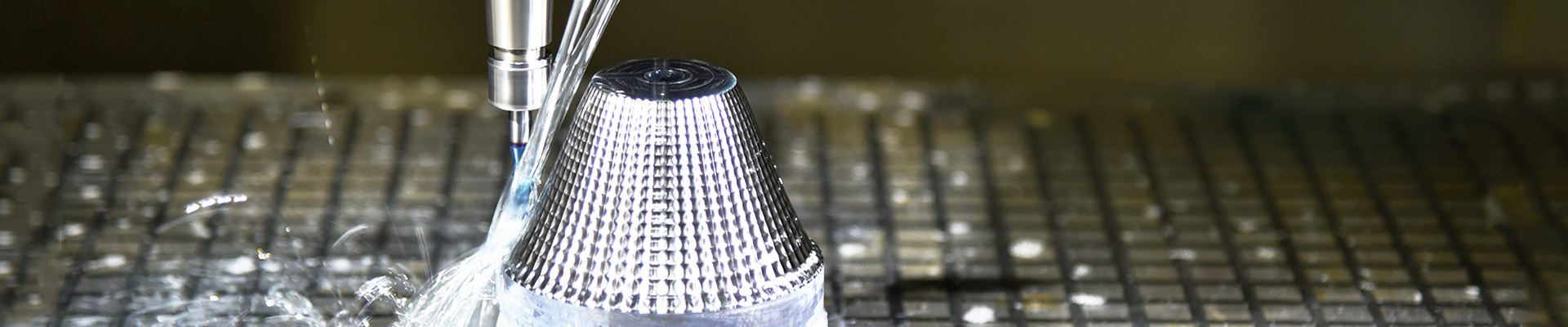

Precision Machining Workshop

Equipped with state-of-the-art processing and testing equipment from leading brands like Toshiba, Sodick, Beijing Jingdiao, and SanGuang. The machining precision reaches up to 0.001 mm. Surface roughness can achieve 0.08 μm.

Material Assurance

Only first-tier domestic and international brands of materials are used. Mold cores and frames that meet hardness requirements is must.

Process Control

All procedures related to the details of mold processing, precision, structural design, lifespan, efficiency, inspection, maintenance, safe use, and mold identification are strictly standardized.

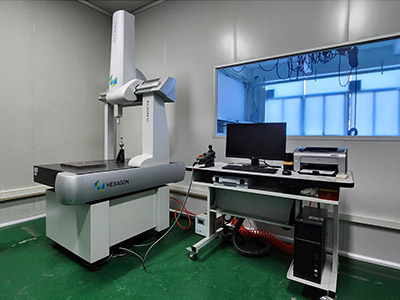

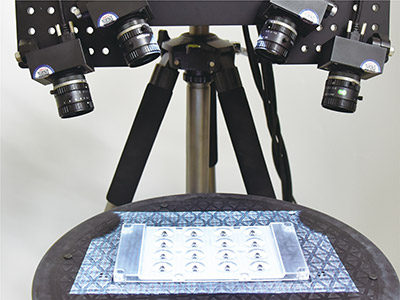

Mold Measurement

3D Coordinate Measuring Machine (CMM), Optical Magnifiers, 2D Measuring Insurtment, Surface Roughness Testers, Digital Height Gauges and Calipers are used to comprehensively inspect the appearance, dimensions, and functionality of molds.

We actively promote sustainable development through wastewater recycling, waste recovery, and energy conservation and emission reduction. Simultaneously, we implement safety management measures, including fire drills, monthly safety training, noise control, and comprehensive personal protective equipment, to ensure the safety and health of our employees. These practices not only promote the sustainable development of our factory but also create a safe, clean, and efficient working environment for our employees.

Greater Light Efficiency, Save More Energy